Download Now

Introduction

In an increasingly dynamic energy landscape, businesses and critical infrastructure demand reliable, efficient, and economically viable power generation solutions. While traditional diesel generators have long served as the standard for emergency standby power, the evolving market, environmental considerations, and advancements in technology are highlighting the advantages of natural gas generator solutions. This paper examines the comprehensive total cost of ownership (TCO) and significant operational benefits that natural gas generators offer, demonstrating their long-term economic advantages and strategic value. Natural gas, as a readily available and cleaner-burning fuel, presents a compelling alternative for emergency standby and demand response applications. Beyond the initial capital investment, a holistic view of ownership costs reveals substantial savings and operational efficiencies that can significantly impact an organization’s bottom line and operational resilience.

Total Cost of Ownership (TCO) Analysis

The total cost of ownership extends beyond the initial capital expenditure. TCO encompasses all costs associated with acquiring, operating, and maintaining a generator throughout its service life, typically 20-25 years. For natural gas generators,

this analysis consistently reveals a more favorable long-term financial outlook compared to other fuel types.

Capital Costs

While the initial capital expenditure for natural gas generators can be higher than diesel units of similar capacity, this difference is often offset by reduced infrastructure requirements and the elimination of certain recurring costs. For instance, natural gas units do not require large, dedicated on-site fuel storage tanks, which can be a significant cost and space consideration for the project. The connection to an existing natural gas pipeline simplifies fuel logistics and eliminates the need for fuel deliveries.

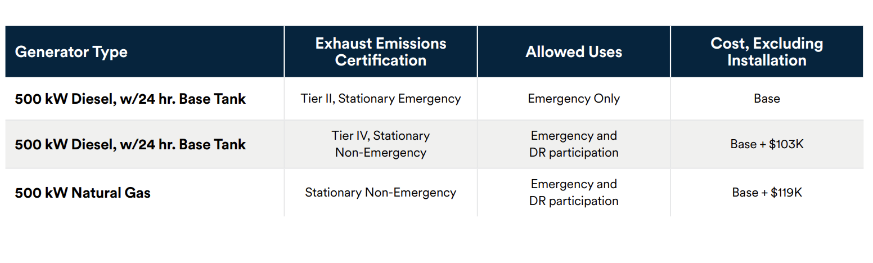

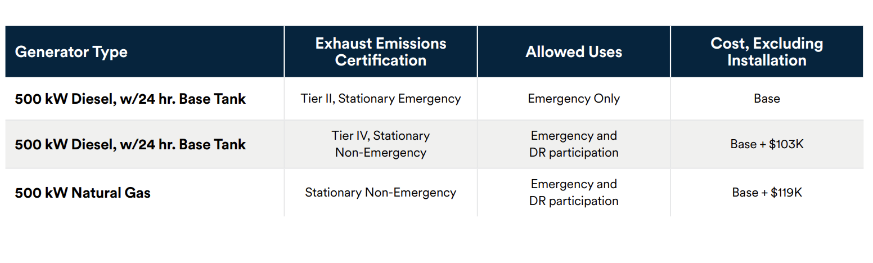

The example below illustrates nominal pricing for various 500 kW generator sets equipped with sound attenuated enclosures. While the Tier II diesel engine has a substantially lower initial cost compared to the Tier IV diesel or the natural gas engine; only the latter two meet the tight exhaust emissions limits required to participate in demand response programs.

Fuel Costs

Fuel represents one of the most substantial ongoing operational costs for any generator. Natural gas typically offers an advantage in this area due to its:

- Lower and More Stable Pricing: Historically, natural gas prices have been more stable and generally lower than diesel prices, which are often subject to greater volatility influenced by global oil markets. This predictability allows

for more accurate budgeting and reduces exposure to sudden price spikes. On a unit energy basis, using natural gas is typically less expensive than generating the same amount of energy with diesel fuel.

- Elimination of Fuel Delivery and Storage Costs:

Unlike diesel, which requires regular replenishment and dedicated, often regulated, on-site storage, natural gas is delivered continuously via the local gas company. This eliminates the costs associated with fuel transportation,

storage tank maintenance, and environmental compliance related to on-site fuel storage.

- No Fuel Degradation or Polishing: Diesel fuel can degrade over time due to microbial growth, water contamination, and oxidation, leading to the formation of sludge, sediment, and acids. This degradation can clog fuel filters, damage

fuel injectors, and ultimately lead to engine failure. “Fuel polishing” is a maintenance process involving filtration and conditioning of stored diesel fuel to remove contaminants and water, thereby maintaining fuel quality and preventing

these issues. Natural gas, delivered via pipeline, does not suffer from degradation issues, eliminating this costly and time-consuming maintenance expense and ensuring fuel readiness without intervention.

- Compliance with NFPA 110 Fuel Quality Testing Requirements: For emergency and legally required standby power systems, compliance with the routine maintenance and operational testing specified in Chapter 8

of NFPA 110 (Standard for Emergency and Standby Power Systems) is critical. NFPA 110 (8.3.7) mandates that diesel fuel stored for emergency generators must be tested at least annually to ensure its quality meets specified

parameters for water content, sediment, and microbial contamination. This testing, and any subsequent remediation efforts like fuel polishing or replacement, represent additional recurring costs and logistical burdens

for diesel generator owners. Natural gas generators do not require fuel testing, further simplifying maintenance and reducing operational expenses.

Reduced Maintenance Expenses

Natural gas generators generally incur lower maintenance costs over their operational life due to several inherent characteristics of the fuel and engine design:

- Cleaner Combustion: Natural gas burns cleaner than diesel, producing fewer particulate emissions and less carbon buildup within the engine. This cleaner combustion leads to reduced wear and tear on engine components,

extending the lifespan of parts and reducing the frequency of maintenance interventions.

- Extended Service Intervals: The cleaner operation often translates to longer intervals between oil changes, and other routine maintenance tasks. This reduces labor costs and the expense of consumables.

- Less Frequent Load Banking: Diesel generators require regular load banking or loaded exercise cycles to prevent “wet stacking” (unburned fuel accumulation due to light-load operation). Natural gas generators are less

susceptible to this issue, reducing the need for costly and time-consuming load banking exercises. However, loaded exercise cycles are also recommended on natural gas generators to ensure operational readiness. (NFPA 110,

8.4.2.1.2)

- Tier 4 Considerations: Some markets that fail to meet National Ambient Air Quality Standards (non-attainment areas) have introduced strict exhaust emissions limits (Tier 4) for standby and demand response rated gensets. This

leads to exhaust after-treatment systems for diesel generators, increasing the cost over an “emergency only” diesel generator by 50% or more. Alternatively, natural gas engines can be equipped with a simple, three-way catalyst

to comply with strict exhaust emissions limits.

Opportunities for Revenue Generation: Demand Response Programs

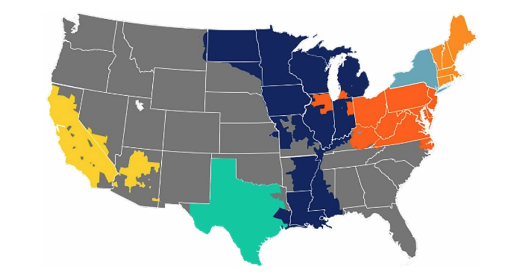

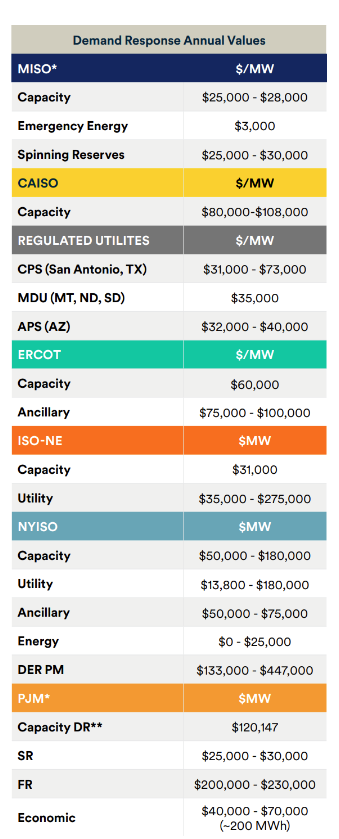

Beyond cost savings, natural gas generators can transform from a pure cost center into a potential revenue stream through participation in demand response (DR) programs. These programs, offered by utilities and grid operators, incentivize customers to reduce or shift their electricity consumption during periods of high demand or grid instability.

By utilizing their natural gas generators to offset grid power during peak times, businesses can earn significant payments from utilities. This not only enhances the economic viability of the generator investment but also contributes to grid stability and energy independence. The continuous fuel supply of natural gas units makes them ideal candidates for sustained participation in such programs.

The financial incentive for participating in demand response programs can overcome the higher initial purchase cost of a generator set equipped with an engine certified to meet the tighter non-emergency emissions standards. In some markets, a DR enabled generator set can show a positive return on investment over its operating life.