Find a Distributor

Use our dealer locator to find industrial sales and service dealers

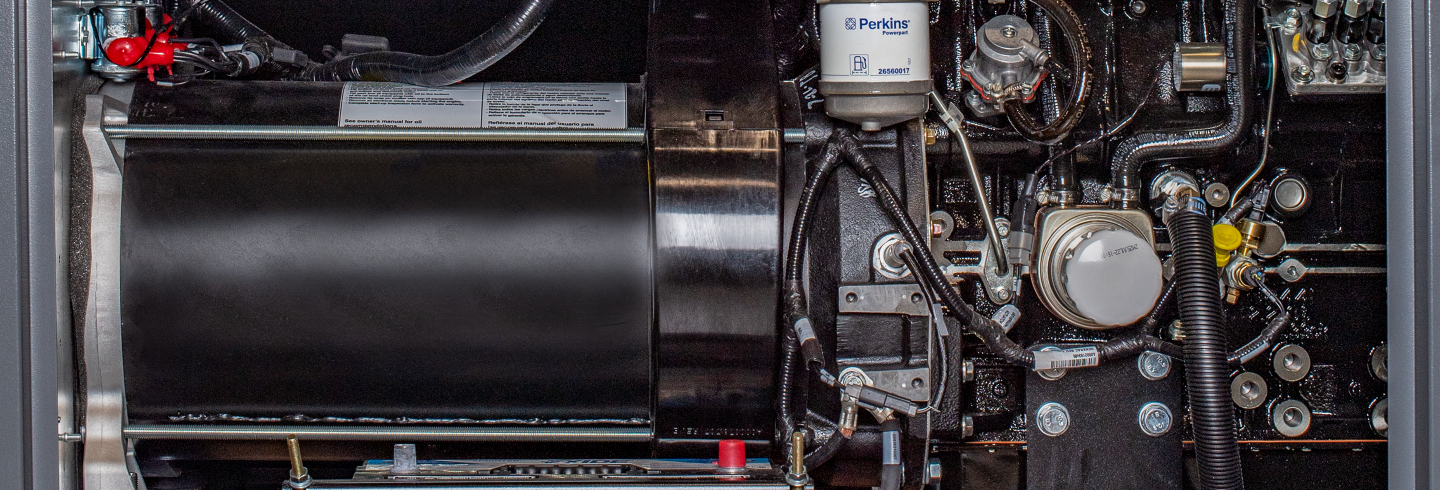

Diesel generators are the established standard for power generators, however several options are emerging to address issues such as smart grids, grid reliability, and environmental regulations. Fuel prices, supply, and maintenance are key factors in lifecycle costs and reliability for power generation.

Several factors favor the use of gaseous fuels :

- Relative fuel prices between 15 ppm ultra-low sulfur diesel and natural gas widening

- Forecasts of domestic natural gas availability extremely robust

- Energy and environmental policies now incorporate Full Fuel Cycle analysis, bolstering gaseous fuels

- Lifecycle costs for gaseous generating sets are improving, including power density (first cost), fuel economy and maintenance costs

While these gaseous fuel options are not viable for Critical Operations Power Systems (NFPA 70 Article 708), natural gas, dual-fuel or bi-fuel generator equipment can provide advantages in reliability and lifecycle costs for many backup power applications.

Reliability |

Pipeline provides weeks to months operation | On-site supply limited to 2 - 3 days | Extends supply using natural gas; still limited by on-site storage |

Cost Savings |

Historically low natural gas prices; forecasts of domestic natural gas supply extremely robust | Fuel costs for 15 ppm ultra-low sulfur diesel higher relative to natural gas Added costs for fuel replacement; 1-year storage life Added infrastructure (storage tank, spill containment, etc.) |

Lower fuel costs than 100% diesel Added costs for fuel replacement; 1-year storage life Added infrastructure (storage tank, spill containment, etc.) |

Performance |

Proven reliability and performance | Proven reliability and performance | No change to power rating with similar cycle efficiency as diesel |

Emissions |

Lower NOx, CO2 and particulates than diesel | Higher NOx, CO2 and particulate emissions | Significant decrease in PM emissions; lower CO2 emissions than diesel |

Safety Concerns |

None | On-site storage presents moderate safety issues | Improves on-site diesel storage, still presents a moderate issue |

An Upward Trend for Choosing Natural Gas:

More AHJ's are recognizing natural gas generators for off-site fuel choice

Natural gas has been gaining popularity across a range of industrial applications due to influencing factors such as its stability and reliability, its cost effectiveness, its clean burning nature, and its resilient infrastructure. Read more »

When designing generator systems, engineers must ensure that the generators and the building electrical systems they support are approriate for the application.

Generac has made a fully customizable total cost of ownership tool to perform your own customized analysis for your unique situation.

AGA published a report in 2017 examining the diversity within the commercial segment of the natural gas market to shed light on the range of customers, technologies and end-uses that serve this important backbone of the U.S. economoy.

Use our dealer locator to find industrial sales and service dealers